Budgeting and Financial Planning for a Cannabis Extraction Businesses

Extraction Lab Startup Costs – Financial Planning and Modeling for a Cannabis Extraction Facility Planning an extraction lab can be

Minnesota Cannabis Business Consulting

Cultivation, Extraction & Retail Consulting and Licensing Documentation

Most cultivation facilities and hemp production projects include extraction as a key component of their production operations. This makes perfect sense given the fact that the lower parts of the plants contain flower sites with plenty of cannabinoids and terpenes but aren’t worth the labor investment to trim for smokable flower material. Further, vape cartridges (carts) and other types of extracted cannabis concentrates are gaining more and more market share as the industry develops. Many of the users new to cannabis gravitate towards non-smoke ingestion methods such as edibles, capsules and tinctures. In some states, the market for extracted cannabis products represents more than 2/3 of all sales.

Most cultivation facilities and hemp production projects include extraction as a key component of their production operations. This makes perfect sense given the fact that the lower parts of the plants contain flower sites with plenty of cannabinoids and terpenes but aren’t worth the labor investment to trim for smokable flower material. Further, vape cartridges (carts) and other types of extracted cannabis concentrates are gaining more and more market share as the industry develops. Many of the users new to cannabis gravitate towards non-smoke ingestion methods such as edibles, capsules and tinctures. In some states, the market for extracted cannabis products represents more than 2/3 of all sales.

I’m Chase Huff, and I’d like to help you design and implement your cannabis extraction project.

How do you know which types of extraction machine and methods to use? Read on…

Extraction is a process of removing active compounds from plant biomass, and there are various methods to choose from in order to accomplish this goal. Different methods of extraction will produce different outcomes, so it is important to have a clear understanding of what kind of products you intend to make when deciding what method of extraction to use. Each method is also unique as it relates to capital expenses, operating costs, post-extraction processing, safety, and the products that can be made. Here we will discuss how these methods differ and why you may select one method over another or why you may want to incorporate multiple methods into your extraction and manufacturing operations.

Hydrocarbon extraction utilizes Butane and Propane as solvents. These non-polar solvents have greater selectivity for the mainly non-polar compounds that we want to extract from the cannabis plant; cannabinoids and terpenes. This selectivity also leads to efficiency, and hydrocarbon extractions can be performed rather quickly with small and larger batch sizes leading to a suitable throughput for most cannabis operation. Part of this efficiency is due to the fact that hydrocarbon extraction tends to not extract as many of the non-polar waxes and fats that other methods may co-extract with the desired molecules. In terms of post-extraction processing, hydrocarbon extraction does require some extensive solvent recovery in order to remove the butane and/or propane from the cannabis concentrates. This process adds to the overall processing time and reduces some of the overall efficiency of this method.In terms of capital costs, closed-loop hydrocarbon extraction systems are generally cheaper than CO2 or Ethanol systems but they do require a C1D1 extraction room. A C1D1 extraction room, is a building code designation that is necessary in order to meet fire code safety requirements while using these explosive and highly flammable solvents. Hydrocarbon extraction is the least safe cannabis and hemp extraction method and has been banned from use in certain regions due to its risk. That being said, hydrocarbon extraction is one of the best for producing dabbable concentrates such as wax, shatter, badder, diamonds, and live resin dabs and vape carts.

Hydrocarbon extraction utilizes Butane and Propane as solvents. These non-polar solvents have greater selectivity for the mainly non-polar compounds that we want to extract from the cannabis plant; cannabinoids and terpenes. This selectivity also leads to efficiency, and hydrocarbon extractions can be performed rather quickly with small and larger batch sizes leading to a suitable throughput for most cannabis operation. Part of this efficiency is due to the fact that hydrocarbon extraction tends to not extract as many of the non-polar waxes and fats that other methods may co-extract with the desired molecules. In terms of post-extraction processing, hydrocarbon extraction does require some extensive solvent recovery in order to remove the butane and/or propane from the cannabis concentrates. This process adds to the overall processing time and reduces some of the overall efficiency of this method.In terms of capital costs, closed-loop hydrocarbon extraction systems are generally cheaper than CO2 or Ethanol systems but they do require a C1D1 extraction room. A C1D1 extraction room, is a building code designation that is necessary in order to meet fire code safety requirements while using these explosive and highly flammable solvents. Hydrocarbon extraction is the least safe cannabis and hemp extraction method and has been banned from use in certain regions due to its risk. That being said, hydrocarbon extraction is one of the best for producing dabbable concentrates such as wax, shatter, badder, diamonds, and live resin dabs and vape carts.

CO2 extraction is performed by using temperature and pressure to control the nature of the CO2 molecules to act like a solvent. Through the control of temperature and pressure, CO2 can be brought to its supercritical fluid state or its subcritical state in order to produce extracts from cannabinoids. Both states have an individual purpose in cannabis extraction.

One of the greatest benefits to CO2 extraction is its tune-ability and selectivity. With the proper protocols for controlling temperature and pressure, the extractor is able to target specific subsets of molecules in the biomass. For example, if you wanted a waxier extract for topical manufacturing or a terpene rich fraction, you can change your parameters to get your intended outcome. No other method of extraction offers this kind of selectivity and tune-ability. The downsides to CO2 extraction are the expensive capital investment costs and the lower throughput. These systems require expert engineering and sophistication that are not cheap, and each extraction batch takes significantly more time to run than other extraction methods. On the other hand, CO2 is a non-toxic solvent that evaporates out of the cannabis concentrate and does not require post-extraction processing unless you want to remove co-extracted fats and waxes. This method is generally regarded as the best method for producing medicinal-grade products due its lack of toxicity and residual solvents.

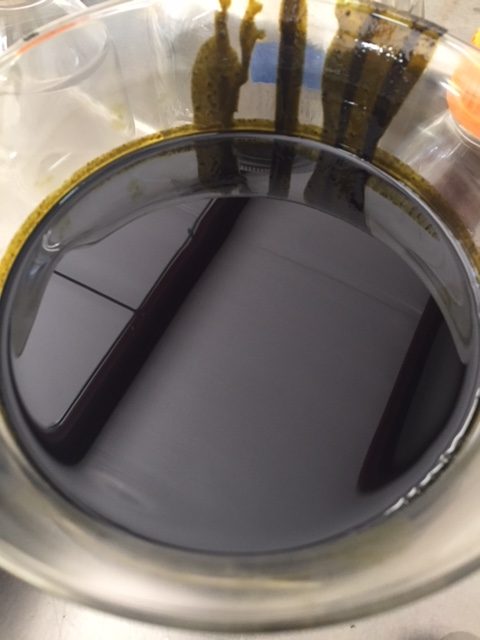

Ethanol, being a slightly polar substance, is much more aggressive and less selective as a solvent. This means that ethanol extracts more total compounds from the plant, which can be good for those who want to produce a more broad spectrum extract. Often times ethanol extraction is done at very cold temperatures in order to reduce the strength of the solvent, which reduces the amount of undesired compounds that are co-extracted with the desired compounds. This method also has the highest throughput of any other extraction methods and is great for large scale extraction. Due to the nature of ethanol as a solvent, there is more post-extraction processing necessary to produce higher grade concentrates.

Compared to hydrocarbon or CO2 extracts, the cannabinoid potency is generally lower in crude ethanol extracts prior to post-extraction processing. These extracts are typically “cleaned up” using methods such as winterization, distillation and chromatography. The crude oil can also be sold as what is commonly referred to as “Rick Simpson Oil” and has been the popular choice for cancer patients and those who seek to utilize cannabis for its full spectrum of medicinal properties. Although not nearly as explosive and flammable as butane and propane, ethanol is flammable and does require an extraction space meeting C1D2 requirements (less stringent than C1D1). Depending on the scale of ethanol extraction, the capital costs can be similar to CO2 but the throughput is much higher and thus ROI is realized sooner.

Compared to hydrocarbon or CO2 extracts, the cannabinoid potency is generally lower in crude ethanol extracts prior to post-extraction processing. These extracts are typically “cleaned up” using methods such as winterization, distillation and chromatography. The crude oil can also be sold as what is commonly referred to as “Rick Simpson Oil” and has been the popular choice for cancer patients and those who seek to utilize cannabis for its full spectrum of medicinal properties. Although not nearly as explosive and flammable as butane and propane, ethanol is flammable and does require an extraction space meeting C1D2 requirements (less stringent than C1D1). Depending on the scale of ethanol extraction, the capital costs can be similar to CO2 but the throughput is much higher and thus ROI is realized sooner.

In recent years solventless methods of cannabis extraction have really taken off in the industry as a means of producing a high quality product that connoisseurs prefer. Solventless extraction means just that–the desired compounds are removed from the plant material without using a chemical solvent. These extracts can be made in various ways but here I will describe the 2 common ways that we see these extracts produced on a commercial scale.

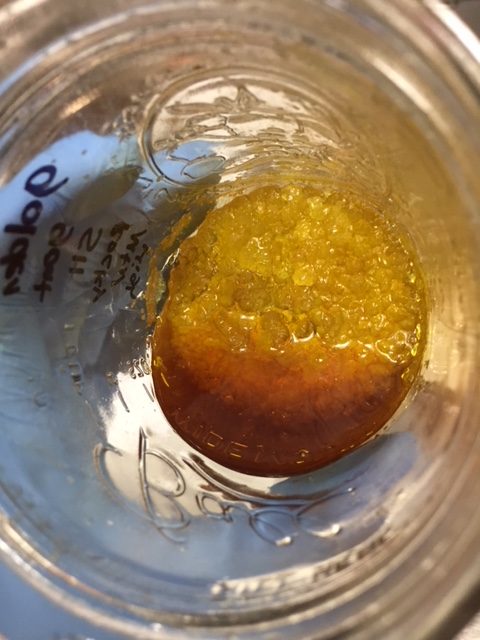

The first method is a mechanical extraction process using ice water. The “ice water hash” process uses ice water to freeze the trichomes on the flower surfaces, and then mechanical agitation is used to knock the trichomes off of the plant material. The trichomes are then filtered out of the water using various sizes of micron screens to collect different quality levels of resin glands. This “ice water hash” or “bubble hash” can be dried and sold as-is, and many people enjoy dabbing this product or adding it on top of smoked flower.

The second common method of solventless extraction is referred to as “rosin pressing” and utilizes heat and pressure to essentially melt the desired compounds from the flower material. This process of rosin pressing can also be done on to ice water hash which is what is commonly done to produce the most premium rosin products on the market. With post-processing performed on the rosin, it can be made into different consistencies and can even be used to form crystalline THCA, or “diamonds” as many people refer to them, just like live resin can do after it is produced from hydrocarbon extraction. This method requires a much lower capital cost, is extremely safe, has a decent throughput, and produces fantastic products that have no residual solvent and thus are great for medical patients and recreational consumers alike. These products also command a higher price point. The main downside to solventless cannabis extraction is that it has a much lower yield than other forms of extraction and not all cultivars yield well with this method. It takes extra experimentation to dial it in.

The second common method of solventless extraction is referred to as “rosin pressing” and utilizes heat and pressure to essentially melt the desired compounds from the flower material. This process of rosin pressing can also be done on to ice water hash which is what is commonly done to produce the most premium rosin products on the market. With post-processing performed on the rosin, it can be made into different consistencies and can even be used to form crystalline THCA, or “diamonds” as many people refer to them, just like live resin can do after it is produced from hydrocarbon extraction. This method requires a much lower capital cost, is extremely safe, has a decent throughput, and produces fantastic products that have no residual solvent and thus are great for medical patients and recreational consumers alike. These products also command a higher price point. The main downside to solventless cannabis extraction is that it has a much lower yield than other forms of extraction and not all cultivars yield well with this method. It takes extra experimentation to dial it in.

If using a solventless extraction method, we recommend combining it with a solvent-based extraction method so that processed plant material can be further processed to remove all valuable compounds, resulting in zero wasted material.

We’d love to help you design, plan and implement your cannabis or hemp extraction facility.

Extraction Lab Startup Costs – Financial Planning and Modeling for a Cannabis Extraction Facility Planning an extraction lab can be