Category: Minnesota Cannabis Facility Design

Minnesota Cannabis Facility Design – Let’s Get Your Project Handled Right

Hi, I’m Jennifer Martin, a veteran indoor grower, facility designer and licensing consultant. I can help you understand and execute the whole process of going from preliminary to final license approval with the Minnesota Office of Cannabis Management (OCM).

Hi, I’m Jennifer Martin, a veteran indoor grower, facility designer and licensing consultant. I can help you understand and execute the whole process of going from preliminary to final license approval with the Minnesota Office of Cannabis Management (OCM).

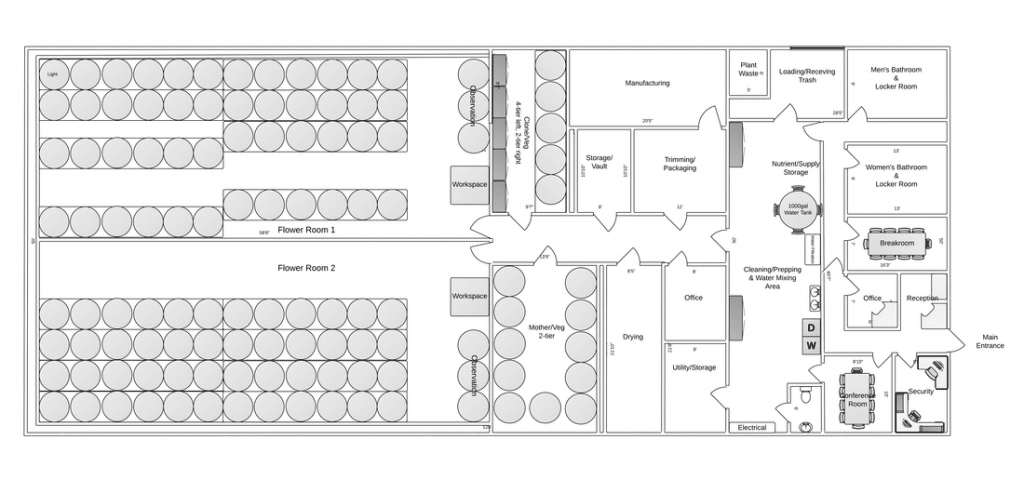

One of the big projects to be done is the facility design, which is created by multiple experts who come together and provide a formal set of documents that will comply with local and state requirements.

The OCM requirements are listed in the “Site, Security, and Operations Final Plans of Record” and are listed below. Local requirements will vary based on your jurisdiction (I can explain more about how to go about this over the phone.)

To get your project going, I have collaborations with all of the necessary contractors who need to be involved with creating compliant floor plans. The architect will be the main coordinator of all visual documents, and I personally oversee all written answers that must be provided in your Final Plans.

My prices are competitive, I provide rapid, thorough communication, and I will make sure you get to the finish line and get approval from the OCM to begin operations as quickly and smoothly as possible.

OCM Facility Design Requirements

These items are all to be included in a single computer file to be uploaded in the Accela Portal:

- Fire and smoke detection systems [Minn. Admin. R. 9810.1102 subp. 3(A)]

- Carbon monoxide detection systems [Minn. Admin. R. 9810.1102 subp. 3(B)]

- Enclosed toilet facilities [Minn. Admin. R. 9810.1100 subp. 6(A)]

- Product storage areas [Minn. Admin. R. 9810.1104]

- Limited-access areas and restricted-access areas [Minn. Stat. Sec. 342.24 subd. 3]

- Ventilation and filtration systems [Minn. Stat. Sec. 342.24 subd. 4]

- Planned square feet of space for licensed activities [Minn. Stat. Sec. 342.14 subd. 1(a)(5)]

- Planned square feet or acres of space for cultivation (if applicable) [Minn. Stat. Sec. 342.14 subd. 1(a)(5)]

- Planned square feet of space for manufacturing (if applicable) [Minn. Admin. R. 9810.2102 subp. 2(2)]

- Planned square feet or acres of plant canopy (if applicable) [Minn. Stat. Sec. 342.14 subd. 1(a)(5)]

- Planned square feet or acres of space for retail sales (if applicable) [Minn. Stat. Sec. 342.14 subd. 1(a)(5)]

- Manufacturing equipment (if applicable) [Minn. Admin. R. 9810.2102 subp. 2(2)]

- Separate manufacturing equipment used for product received from unlicensed individuals (if applicable) [Minn. Stat. Sec. 342.26 subp. 3(e)]

- All points of ingress and egress [Minn. Stat. Sec. 342.14 subd. 1(a)(6)]

- Windows and doors, with identification of locks [Minn. Admin. R. 9810.1500 subp. 12]

- Alarm systems, including control panels and alarm sensors [Minn. Admin. R. 9810.1500 subp. 8]

- Video surveillance cameras and storage devices, including identification of video area coverage [Minn. Admin. R. 9810.1500 subp. 9]

- Lighting [Minn. Admin. R. 9810.1500 subp. 10]

- Lock keypads [Minn. Admin. R. 9810.1500 subp. 12]

- Fencing or locked gates (if applicable) [Minn. Admin. R. 9810.1500 subp. 14]

The purpose of this article is to break this list down into actionable steps for cannabis business applicants since you can’t submit your Final Plans of Record and finalize your license until it is completed.

To be clear about our role, we offer cultivation and manufacturing facility design services and we offer the narrative text component of the Final Plans of Record, which consists of dozens of descriptions and procedures about how your company will operate.

We can also offer advice on how to proceed with the above requirements because there are quite a few ways to go about it. We will explain most of them here.

Who Manages Your MN Cannabis Facility Design Process?

We expect that applicants will do most of their own project management. There are project management companies who will take on the role of managing all of the contractors who must come together to create your design plans, but having someone do that adds quite a bit of cost and risks the project not going exactly how you want it to.

We expect that applicants will do most of their own project management. There are project management companies who will take on the role of managing all of the contractors who must come together to create your design plans, but having someone do that adds quite a bit of cost and risks the project not going exactly how you want it to.

That said, you can expect some of the contractors to manage other contractors. For example, the architect is primarily responsible for the drawings that get created and, as such, will gather information and drawings from other contractors in the group, such as the engineers (you need them for the ventilation and filtration systems piece of the above list), and the fire suppression expert/company (needed for the smoke detection and carbon monoxide detection pieces). You can find your own experts in this area and ask your architect to work with them, or you can ask your architect to find them for you. The same is true for the security components. You can choose your own security company for the components of the floor plan that must show the alarms, video surveillance, lighting, keypads and fencing, or your architect can likely find one for you.

There are other types of contractors needed for facility design in general that are not explicitly part of the OCM floor plan requirements. Those are the electrical and mechanical engineers. Mechanical engineers can do your ventilation and filtration systems diagrams, but their much bigger job is to design your air conditioning and dehumidification (HVAC) systems. This is a particularly significant task for MN cultivation facility designs.

Before we move on to the next section, it’s important to note that the layout requirements for the OCM are not the same as those that will be required for your local building permit department. We don’t want you getting stuck in a situation where you manage to produce a whole set of plans that need to be revised for a different department. For this reason, your architect must be clear with you from the beginning that he/she is accommodating both sets of requirements and producing a single set of documents that work for both jurisdictions.

How Much Will an MN Cannabis Facility Design Cost?

Because each project will have a different group of contractors involved, the costs will vary, but everyone required for this type of work is an expert and they generally charge between $150-$300 per hour for their work. We’ve seen architects charge anywhere from $15,000 to $40,000 for cannabis facility design plans. Sometimes security companies will do designs for a reduced price because you agree to purchase hardware, installation and monthly video storage services from them. A ventilation and filtration systems diagram might only cost $800, but the design for your HVAC system could cost upwards of $10,000 and that doesn’t include equipment or installation. It’s important to call around and compare quotes and, if you are working with a tight budget, do as much of the work as you can on your own (like installing your own security equipment).

Minnesota Dispensary Design

What if you are only opening a dispensary in Minnesota and not a cannabis production facility? Well, the requirements are all still the same, but the cost and work that go into it will be much simpler. Dispensaries are really just highly regulated retail stores, so there are extra security and inventory control considerations, but the dispensary facility is fairly simple in comparison to cultivation or manufacturing. The climate controls, for example, are no different than what you’d need in any typical store or office building.

What if you are only opening a dispensary in Minnesota and not a cannabis production facility? Well, the requirements are all still the same, but the cost and work that go into it will be much simpler. Dispensaries are really just highly regulated retail stores, so there are extra security and inventory control considerations, but the dispensary facility is fairly simple in comparison to cultivation or manufacturing. The climate controls, for example, are no different than what you’d need in any typical store or office building.

The OCM still requires dispensaries to submit ventilation and filtration diagrams because they are concerned about odors creating a nuisance in the neighborhood, so the Minnesota dispensary facility design diagram you submit to finalize your license is essentially the same in terms of complexity as to the other license types.

Retail dispensaries in Minnesota need certain facility design considerations, such as the inflow and outflow of car and foot traffic, a clear demarcation between customer access areas and limited access areas and a mantrap entry room where ID’s can be checked before the customer is able to enter the showroom.

Will My Architect Know How to Design a Cultivation or Manufacturing Facility in MN?

There are two types of architects: Those with cannabis facility design experience and those without. The architects who DO have this type of experience are out of state, but if they are licensed in Minnesota, they can still do the job. Some companies are out there pretending to be cannabis design firms, when they are actually outsourcing the architecture for the purpose of doing your build-out (as general contractors) or selling you equipment. Make sure you ask enough questions to determine which is which.

The disappointing reality, however, is that even the most skilled cannabis facility architects do not know about the on-the-ground reality for growers and cannabis product manufacturers. That’s where we come in. We work with architects and engineers to make sure they know what’s important to growers and extraction businesses. This includes things like accounting for all of the important functions in a cannabis production facility, how the rooms should be oriented and sized, how much heat load needs to be offset with air conditioning and how much moisture needs to be offset by dehumidifiers.

The disappointing reality, however, is that even the most skilled cannabis facility architects do not know about the on-the-ground reality for growers and cannabis product manufacturers. That’s where we come in. We work with architects and engineers to make sure they know what’s important to growers and extraction businesses. This includes things like accounting for all of the important functions in a cannabis production facility, how the rooms should be oriented and sized, how much heat load needs to be offset with air conditioning and how much moisture needs to be offset by dehumidifiers.

Our company owner, Jennifer Martin, has completed many facility designs in the past decade, working on teams with architects and engineers. She has taken GMP cannabis facility design classes (Good Manufacturing Practices) and has seen the pitfalls associated with improper sizing or exclusion of certain key spaces. Jennifer serves the role of providing a conceptual design based on a line drawing of your building, and then participates in weekly meetings with your design team to ensure all of the rooms and spaces are present, sized properly and flow well into each other. She also provides estimated yields, plant numbers, heat loads, moisture loads, and other critical information to the design team.

For project owners who want extra support, Jennifer’s help can extend to equipment recommendations, how racks and other furnishings will sit in each room, and even genetics acquisition. Jennifer is an award-winning indoor grower with 30 years of cultivation experience. She will ensure that your MN cultivation facility design is done in user-friendly, economical and flexible way. Chase Huff is our cannabis manufacturing and facility design expert. He offers the same support Jennifer offers, but for extraction, manufacturing and tissue culture business planning in Minnesota. Don Duncan is our Dispensary Design and Operations expert.

Can I Use a Minnesota Based Architect with No Cannabis Facility Design Experience?

Yes! If you have a local architect you really like, we can work with him/her ensure they know the important and unique considerations for cannabis dispensaries, grow facilities and manufacturing facilities. You will want that architect to at least have experience with commercial buildings. A residential architect is unlikely to be a good choice.

Example Step-by-Step Process for Completing Your Minnesota Cannabis Cultivation, Manufacturing or Retail Facility Design Process

- Choose an architect or ask us for a list of recommendations. Ensure they have seen the OCM’s cannabis design requirements and will include local requirements as part of the design plans they deliver.

- Determine which of the remaining design contractors will be obtained by your architect vs you finding them yourself.

- Find the other contractors you will need and schedule a meeting so everyone can understand the scope of work. The architect will want plans from the other contractors in a certain format, for example, and this type of information should be conveyed early in the process.

- If you haven’t yet secured a properly zoned facility, this should be a very high priority because none of the contractors can start their work without it.

- Choose a company (hopefully us!) to provide the narrative content for your Final Plans of Record. Most of this work can be done without the facility design being completed.

- If you have experience in retail, cultivation and/or manufacturing, you can use graph paper to make a conceptual floor plan to share with the architect. If you don’t, you might want to tap us or another consulting company to do this for you.

- Establish pricing, scope of work and contracts with everyone to get started on the project.

- Hold weekly or twice-per-month virtual meetings to keep everyone on track.

- Ask us any time you aren’t sure what to do next or need extra help bringing all of the pieces together. This isn’t our first rodeo.

Below is the text from our older web page that focuses on the details of cultivation facility design. It’s worth reading if you are new to commercial cannabis cultivation and are setting up a new facility.

Facility design is a part of the business planning process that is worthy of very deep consideration. Some cultivation businesses have failed because of poorly considered layouts and mechanical systems that are difficult to change once the site is set operational.

For example, undersizing the environmental controls is an error that’s almost impossible to overcome. HVAC systems need to have redundancy, backup power, be cleanable outside plant rooms, and be easy to repair. They must be sized properly to remove the massive amounts of moisture created by plant growth. Air circulation must be sufficient to keep all plants swaying in an artificial breeze, and also to keep the upper level flower canopy (in a vertical grow) from getting too hot. The environmental controls, when done correctly, can cost between $100-$150 per square foot as a capital expense, including engineering and installation. The reason it’s worth the money is because failures and inconsistencies in environmental controls are the #2 cause of crop loss. (The #1 cause is acquiring pests from clones brought from other facilities.)

You might have noticed from your research that many indoor cannabis cultivation spaces use 8 or more individual flower rooms that typically measure about 30 ft across and 50-100 ft long. This approach has some good logic behind it. When the rooms are divided and self contained, they can have their own temperature controls, pest treatment practices, and they subdivide the workflow into digestible chunks, so one room can be set up, treated or harvested at a time. Further, with multiple flower rooms, a pest or mold outbreak can be contained to a small percentage of the overall crop.

Being an R&D oriented cultivation consultant and educator, I also like divided rooms because they create a good foundation for controlled experiments. If, for example, you wanted to test the efficacy of a certain amount of Co2 injection, or a type of lighting system or nutrient regimen, doing this in one of your rooms, with another room containing the same cultivars with no other variables, gives you reliable data on which to base protocol changes across the site.

Let’s dig into the grow facility planning process, and all of the major considerations you’ll need to maneuver.

I find that most people who contact my website need a basic primer on the facility design process. They know they want to go into the business, but they need a lot more information in order to proceed successfully.

Of course building a cannabis grow facility is not advised for some people. It’s expensive and complicated and, in many legal cannabis regions, it’s also highly competitive. Indoor plant cultivation requires maintaining tight temperature and humidity ranges, and fresh breezy air movement at all times. Without clean and controlled conditions all the time (literally 100% of the time), plants quickly develop mold, insect and/or nutrient problems that take all of the joy out of being grower and possibly also all of the profit out of being the cultivation facility business owner.

Because so many investors and entrepreneurs are jumping into the cannabis cultivation business lately, an oversupply problem is developing in many places, which is gutting the value of a wholesale pound of finished cannabis flower. For wholesale producers approaching potential buyers, this means that only the highest quality flowers will sell. Anything “B grade” or below ends up going to extraction, fetching about the same price as the cost of production, hence the cultivation project breaks even or loses money.

The Importance of a Having a Great Lead Grower

If you haven’t grown cannabis before, or if you haven’t personally become intimate with the quality differences in various samples of finished cannabis, it’s unlikely that your first cultivation facility will produce easy sellable product in a competitive marketplace. You can possibly overcome the odds by hiring a great grower, but it’s very hard to find one. Almost all of the project managers I’ve encountered believe that they’ve hired a good grower, and a year later, they are looking for a new one. Most of the best commercial cannabis growers either work for themselves or have already been swallowed up by well financed projects.

It takes a uniquely talented person to run a professional cultivation facility. This person needs to be a systems thinker, have management/people skills, be sensitive to micro changes in plant appearance from day to day, and have experience with early recognition of a myriad of common problems cannabis can acquire. S/he needs both a broad sense of project goals and a detail-oriented awareness of plant development and tracking. Start thinking now about how you might find this person. Some of the cannabis staffing companies have resumes from growers with commercial experience from Oregon, Washington, California and Colorado where cultivation has been happening legally for several years already. Your cultivation consultant can help you interview and choose people from these staffing pools.

Construction Planning Process and Build-out

As a project developer, first be aware that ground-up construction will significantly delay the start of cultivation project over leasing a pre-zoned cultivation warehouse or building space. The clients I’ve had who have pursued ground-up construction get bogged down full time for an average of 2-3 years working their way through the permitting and compliance processes. They have often spent over $3 million before breaking ground. If the investors have deep pockets and a lot of patience, then no problem, but usually this delay is a source of major frustration for those involved.

For ground-up facilities, there are many more permits and approvals to obtain, and sometimes deal killers occur, like the discovery of an endangered species nearby or archaeological evidence found on site. Also, neighbors will often stall a cannabis project by objecting at public hearings. Unfortunately, hardly any project proceeds without some kind of unexpected costly hindrance coming out of left field.

Getting into the Details of Cannabis Facility Design

For the sake of getting into some more practical planning information, let’s assume you are either purchasing or leasing a warehouse in a properly zoned cannabis cultivation area. This is the most common scenario and the path of least resistance for any soon-to-be cultivation facility operator. Now what?

There’s actually a fairly typical pathway that must be pursued. Let me break it down for you:

The contractors you will need to hire for construction planning are:

A Cannabis Cultivation Consultant

This is someone who can teach you the different cultivation method options you have to choose from, tell you the costs of the various options, the ease of use, pros and cons, and help you devise a reliable system before you’ve built any walls in the building. Different cultivation methods use room space differently, so the rooms essentially get built around the furniture and the plant canopies. Like any good business person, you need to have a detailed and fairly well guaranteed system planned out in order to hit the ground running. Your cultivation consultant also teaches you how to implement efficient day-to-day operations that minimize labor and supply costs and streamline workflow. Look for a consultant who does not sell products of their own or accept commissions from any equipment companies, but rather, one who has tried many different kinds of cultivation systems and knows how to strike the best balance between low cost, simplicity and large, high quality yields. (Full disclosure: this is a service I provide for controlled-environment marijuana cultivation sites under 50,000 square feet in size.)

A Cannabis Facility Architect

The architect creates submittable drawings for the Planning Department based on a layout and information provided by the cultivation consultant. The architect must be licensed in your state and preferably have some cannabis facility design or other similar design experience.

A Mechanical Engineer

The engineer should have experience designing indoor plant cultivation facilities and will design the system for your environmental controls, electrical and plumbing requirements based on information provided by the cultivation consultant. The engineer will also design back-up power systems and HVAC redundancy so that mechanical failures won’t mean immediate doom for your precious plants. Some architecture firms have engineers on staff, but the bulk of the projects I’ve worked on have hired separate engineering firms. The engineer does not have to be locally licensed, but if s/he is not, you’ll need a locally licensed engineer to stamp the drawings for submittal to the Planning Department before you can begin construction. (Note that the first engineering-related issue you must address is ensuring adequate electrical service to the facility. Service upgrades are usually required and can cost anywhere from $10,000 – $1,000,000 and can take from weeks to months to be completed.)

A General Contractor

This person will need to be licensed in your state and should have applicable construction experience. S/he will take the drawings approved by the Planning Department and start construction. Both the architect and the general contractor should be familiar with the construction codes so that no choices will be made along the way that could jeopardize your project as it moves towards final approval.

Jennifer Martin, M.A. is an award-winning commercial indoor grower from Northern California who consults for licensed cultivation facilities in the US and Canada. She is the winner of the 1998 Bay Area Cannabis Cup, 3rd place winner of the 2025 Aloha Cup, an industry trade show speaker, and has expertise in the areas of rockwool cloning/propagation, custom nutrients, genetics evaluation and acquisition, and facility operations.