HVAC Technologies

What’s the Difference Between Cannabis HVAC Systems? If you’ve been studying cannabis HVAC and Dehumidification (HVACD) options, you’ve probably encountered

Minnesota Cannabis Business Consulting

Cultivation, Extraction & Retail Consulting and Licensing Documentation

The absolute biggest and most consequential investment and planning decision to be made by those building out cultivation facilities is how to climate control the pnt rooms, and this means setting aside adequate investment capital and choosing the right brand and technology of HVAC and dehumidification systems (collectively known as HVACD), so that your system will maintain temperature and humidity set points without any glitches.

The absolute biggest and most consequential investment and planning decision to be made by those building out cultivation facilities is how to climate control the pnt rooms, and this means setting aside adequate investment capital and choosing the right brand and technology of HVAC and dehumidification systems (collectively known as HVACD), so that your system will maintain temperature and humidity set points without any glitches.

If set points are not maintained throughout the day, and over the course of the crop life cycle, your cannabis crop will be much more susceptible to mold and pest problems, as well as to growth rate glitches that will hinder your yields. This is one of the first things we explain to new cannabis production project leaders–nothing is more important than the proper sizing, quality and design of the climate control system.

On the surface, it’s easy to write off cannabis HVACD design as something similar to how an office building would get climate controlled, but there’s SO much more to consider once you look under the hood. This article is a primer on all of the important considerations and expected costs.

Cultivation Sector Consulting does not rep or sell equipment, or take commissions from equipment companies. Our business model is all about giving you unbiased advice on how to choose the best equipment for your project. We work for you and only you.

The first two factors that make cannabis HVACD so unique and industrial are: 1) the large amount of moisture that must be collected from plant transpiration (known as “latent load” in HVAC terminology) and 2) the heat production created by grow lights (known as “sensible load”).

Latent load is a measure of the amount of energy necessary to dehumidify the air in a building. The latent load produced by indoor growing adds up to many times more moisture than would be needed in pretty much any other setting, with the possible exception of heated indoor pools. Plants release moisture as part of their growth process, known as transpiration. Without heavy dehumidification equipment, the room would quickly rise to 100% relative humidity (RH), the plants would stop transpiring (due to ambient air moisture saturation) and mold would quickly form. The crop would be lost.

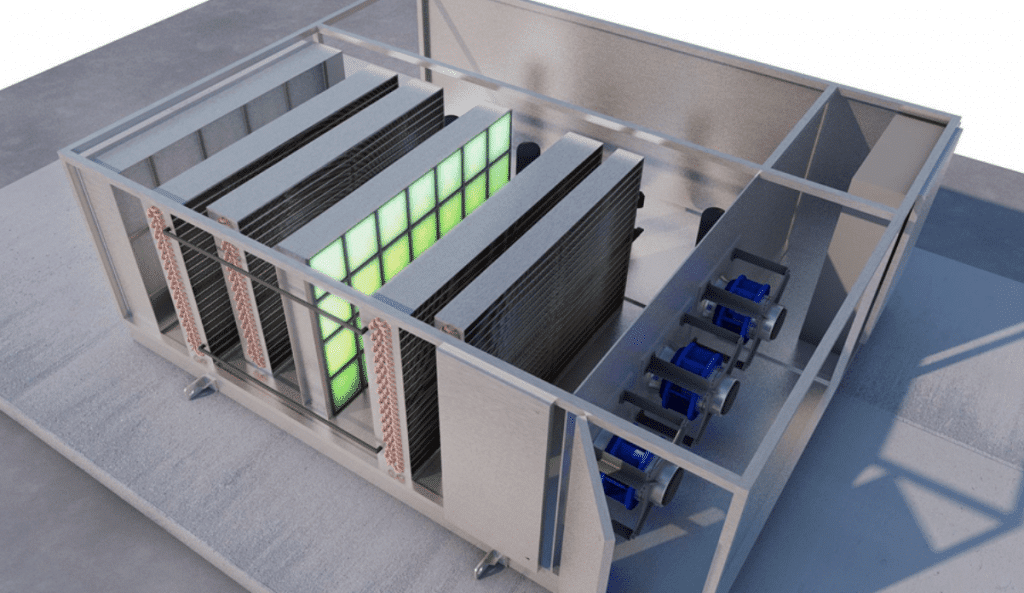

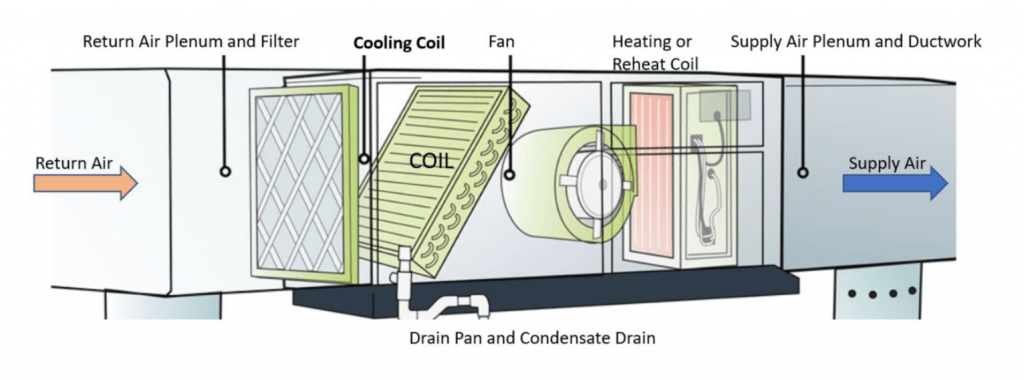

All refrigeration devices; freezers (low-temp refrigeration); refrigerators (medium-temp refrigeration); and air-conditioners (high-temp refrigeration); have within them a cooling coil. The cooling coil can be made primarily for sensible heat removal (comfort cooling) or primarily for latent heat removal (dehumidification). While configurations will vary, this is a typical air handler design:

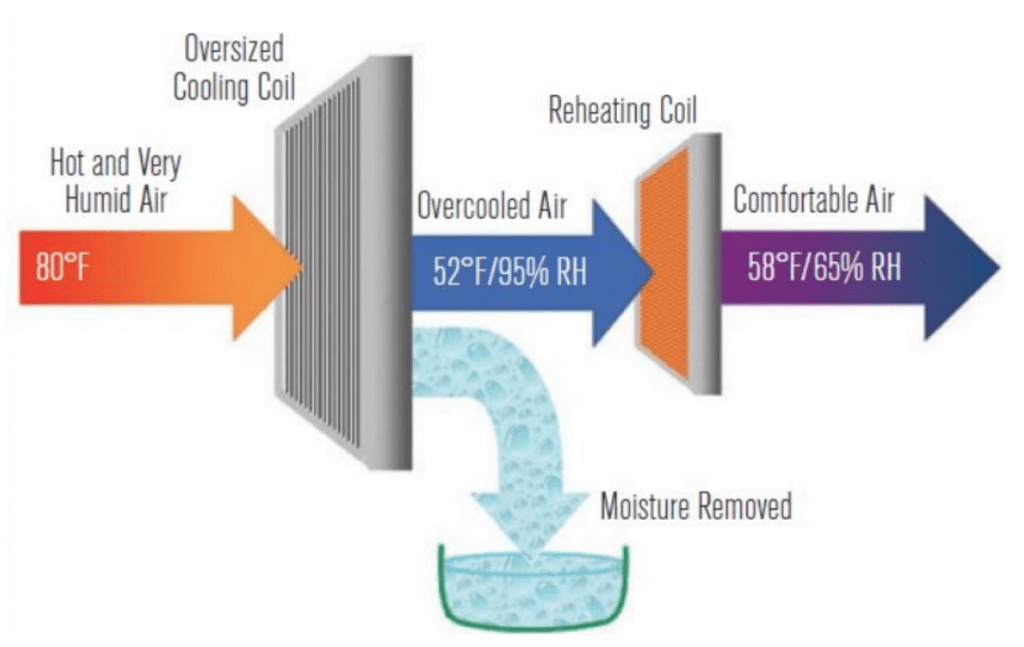

Dehumidification units require colder coil temperatures and deeper/larger coils than the typical comfort cooling coils we all use in our home or office AC systems. Larger coils and colder temperatures require more energy. Cannabis HVACD providers who are in the know are quick to point out that the energy it takes to remove sufficient moisture from the air, and the amount of moisture to be removed, are the primary factors used to determine climate control system capacity

The amount of moisture released into the air in a grow room varies quite a bit depending on plant size, plant health, amount of biomass on each plant, and temperature and relative humidity settings. You don’t want to get caught with insufficient dehumidification, so it’s best to size your systems based on the highest possible amount of moisture removal you’ll ever need. This would be for big, lush, perfectly healthy plants, with the room filled to a high plant density level. A good benchmark for moisture removal requirements under these conditions is 0.25-0.30 gallons per square foot per day. So if your lights cover 16 sqft. each, the maximum water usage per day would be 4-5 gallons. If you have some unusual features to your system, such as ebb and flow irrigation or oxygen infusion, or unusually tall plants, the moisture removal number could be even higher when the plants hit their maximum size and growth rate.

It would be nice if gallons per day of moisture removal was the only metric needed, but there’s actually one more layer of complexity. When plants are flowering, lights are on for 12 hours and off for 12 hours. During the lights-on time, about 70% of all transpiration occurs, with only 30% occurring during lights-off times. This means your dehumidification equipment must be sized for the peak load.

While residential small scale dehumidifiers are sized based on pints per day, commercial grow room dehumidifiers in the United States are sized based on pounds (lbs.) per hour of moisture removal. A gallon of water at 70°F weighs 8.33 lbs.

So if you have 1000 sqft. of densely packed, healthy canopy that’s flowering, you’ll generally be using no more than 400 gallons per day in the room, with 280 gallons of that being used during the 12 hours when the lights are on. 280 gallons/12 hours = 23.33 gallons per hour x 8.33 lbs = 194 lbs/hr of required moisture removal for that room, assuming that the room is insulated and sealed from outside air exchange.

Sensible load is a measurement of the amount of energy that must be removed from the air inside a building to maintain a desired temperature. This is usually the primary capacity sizing factor for comfort cooling. However, in cannabis cultivation, the energy required to remove heat (sensible load) is not as significant in the equation of climate control system sizing as you might think. We’ll explain why-

As mentioned earlier, the mechanical process involved to remove moisture from a room requires larger coils and colder cooling coil temperatures. Moisture collects (condenses) on the cold coil and drips into a collection pan (drain pan), thus removing that moisture from the air. After moisture removal, that cold air is now available to be sent back into the room to offset the heat in the room (the sensible load). Depending on your dehumidification technology, either hot water or a hot gas reheat process (reheat coil) is typically used to reheat the over-cooled air before it is sent back into the room. This prevents the space from over-cooling and also quickly adjusts the relative humidity of the supply air to desired levels.

Because the air was cooled way down for moisture removal, it can also be used to offset a portion of the sensible heat in the grow room, making sensible heat load a secondary, but still important, factor in the equation of how to calculate grow room HVAC system capacity.

Now that you understand grow room climate control better and have some numbers to work from, you can tell the HVACD cannabis climate control companies what they need in order to provide you with a basic quote. We can also do this on your behalf. But there are still some big choices to make and important things to know.

What is the difference in technology, reliability, affordability and features from one cannabis climate control company to the next? That’s what we’d like to help you learn.

Cultivation Sector Consulting has vetted over a dozen of the well known cannabis climate control brands and systems on the market to determine how they differ, what they cost, and the other associated costs you’ll encounter as part of getting your system up and running.

Some basic guidelines that are important to us in how climate control is designed and implemented:

Here’s another other big consideration for choosing your cannabis air conditioning and dehumidification system: Installation cost and complexity.

After you have selected the equipment to be used, a mechanical engineer with cannabis experience should create the design plan that will be used to install the system. A mechanical contractor will need to be hired to follow the design plan and get the system installed. The complexity of the installation can vary depending on the type of system you choose. For example, split systems cost more to install because of the refrigerant lines that must be run from outdoor to indoor units and because they usually have more separate components to install. Packaged units are generally simpler to install, but will involve additional and larger building penetrations since the ducting runs all the way from outside of the building to the grow rooms.

All in all, it’s common to spend as much on engineering and installation as on the equipment itself, turning the total cost of your climate control system into your biggest budgetary line item, at up to 40% of your total project budget.

The ballpark cost for a 1000 sqft. grow room, outfitted with pro quality equipment that maintains set points can run $200,000 – $400,000. It’s an exceedingly high cost, but if you think about how many harvests it takes to pay for it (2-6 at 1.5lbs/light, $1500 value per lb.), or the cost of losing even one crop to insufficient system performance, it all comes into perspective.

With all of the choices available – different technologies, different approaches, different control schemes and pricing all over the map; the HVACD selection process can be very confusing. We are here to help you make a well-informed decision.

Jeff Ledsinger is a 30-year veteran of commercial HVAC and dehumidification systems. He has meticulously collected information about how all of the well known cannabis climate control systems work and what differentiates them from each other. Jeff is available to help you choose the system that best fits your budget and the unique needs of your specific grow facility.

Jeff Ledsinger is a 30-year veteran of commercial HVAC and dehumidification systems. He has meticulously collected information about how all of the well known cannabis climate control systems work and what differentiates them from each other. Jeff is available to help you choose the system that best fits your budget and the unique needs of your specific grow facility.

What’s the Difference Between Cannabis HVAC Systems? If you’ve been studying cannabis HVAC and Dehumidification (HVACD) options, you’ve probably encountered