HVAC Technologies

What’s the Difference Between Cannabis HVAC Systems?

If you’ve been studying cannabis HVAC and Dehumidification (HVACD) options, you’ve probably encountered certain common terms: Mini-splits, split systems, packaged units, chillers, DX, VRF/VRV, coils, evaporators, air handlers, compressors, etc. What IS all this stuff?

We really wish you didn’t have to know (!), but the climate control system in your cultivation facility is the beating heart of your operation. It’s also your most expensive equipment investment, and of all your mechanical systems, this one has the most direct impact on consistent product quality by far. Therefore, in order to stay at the top of your game as a commercial grower, it’s wise to have some basic understanding of the different cannabis HVAC technologies and ensure that the one you choose is a good match for your building, budget and long-term success.

We really wish you didn’t have to know (!), but the climate control system in your cultivation facility is the beating heart of your operation. It’s also your most expensive equipment investment, and of all your mechanical systems, this one has the most direct impact on consistent product quality by far. Therefore, in order to stay at the top of your game as a commercial grower, it’s wise to have some basic understanding of the different cannabis HVAC technologies and ensure that the one you choose is a good match for your building, budget and long-term success.

The first thing to know is that climate controlling an indoor cannabis facility is an industrial application. It takes a whole lot of energy to offset the massive heat and moisture loads that are created by lights and plants. The major functions of the system are cooling (AC) and drying (dehumidification).

Several different technologies of cooling and drying equipment are commonly used in cannabis facilities. They have a range of costs and characteristics, pros and cons, that you will benefit from knowing before you pull the trigger on a new system.

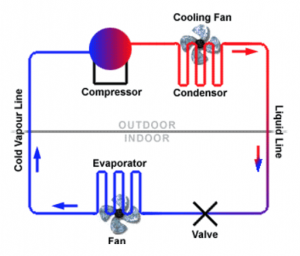

Before explaining the differences between the systems, let’s first look at what they all have in common. They all:

- Move heat from inside the building to outside of the building

- Have condensers

- Have compressors

- Have evaporators

Sometimes the condenser, compressor and the evaporator are together in the same unit (Packaged Unit). Sometimes the evaporator and the condenser/compressor are in separate units (Split System). Of course, there are variations and nuances from system to system, but all are basically the same. The evaporator (cooling coil) picks up heat from the indoor space and the compressor pumps that heat to the condenser where the heat is released. Humidity (water droplets) collects on the cooling coil and is drained away, thus removing moisture from the indoor air.

Some systems are DX (Direct Expansion) – using pressurized refrigerant liquid, an EPA-controlled chemical, to provide cooling/dehumidification; and some systems are Chilled Water – using a cooled liquid instead (water that sometimes contains additives to avert the risk of freezing).

Below is an overview of five basic types of systems currently used in cannabis cultivation and presently available to growers:

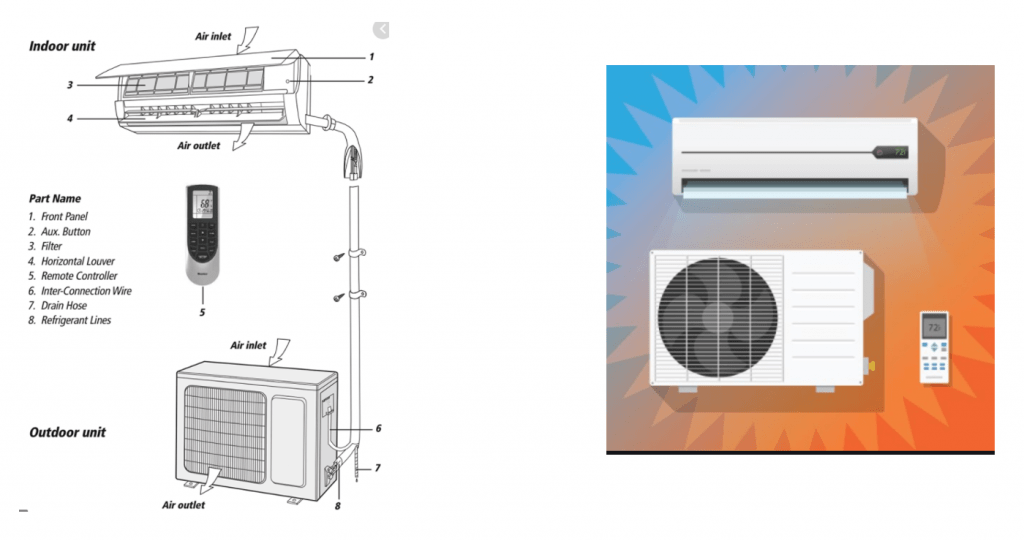

- Mini-Splits Mini-Split or “Ductless” are DX air conditioners made for cooling a single space, or in other words, they are not “central” air conditioners. As the name implies, these are split systems. Usually associated with the high-wall type of indoor units, mini-splits can also have ceiling mounted, floor mounted or ducted indoor units. Mini-splits are great for comfort cooling (people cooling) and they can remove moisture as well, but they will usually need help with moisture removal in cannabis facilities in the form of separate dehumidifiers. Most mini-split systems can vary their capacity to meet the changing needs of the space. Mini-Splits should be considered as existing equipment, made for another purpose, and applied to indoor growing facilities. Coupled with separate dehumidifiers, they can be a cost effective way to control the climate in your cultivation facility.

Mini-splits are common among small-scale, lower budget facilities because they are inexpensive, easy to install, and require only a small hole in the wall for the line set to connect the indoor and outdoor components. On the other hand, long-term users of mini-splits have found that mold often collects in the indoor blowers, they break down frequently, and are virtually impossible to clean. They are not considered to be a viable option for truly professional cultivation operations for all these reasons.

Mini-splits are common among small-scale, lower budget facilities because they are inexpensive, easy to install, and require only a small hole in the wall for the line set to connect the indoor and outdoor components. On the other hand, long-term users of mini-splits have found that mold often collects in the indoor blowers, they break down frequently, and are virtually impossible to clean. They are not considered to be a viable option for truly professional cultivation operations for all these reasons.

- VRF Systems for Cannabis

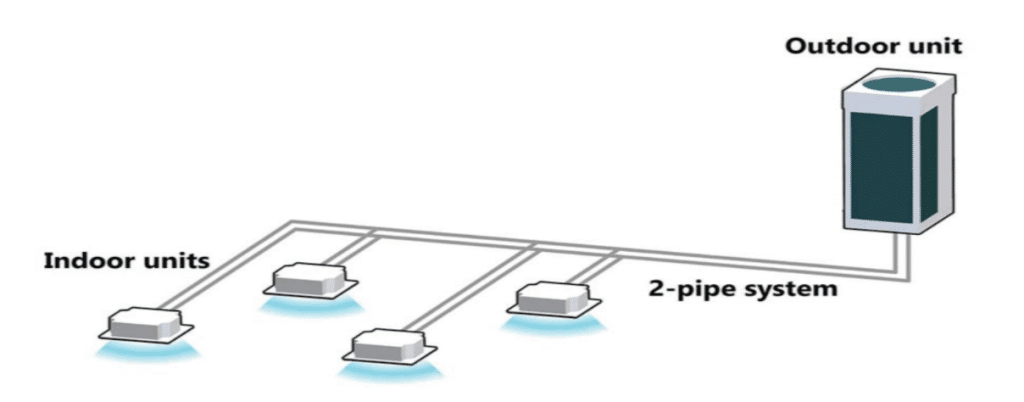

VRF (Variable Refrigerant Flow) Systems are DX split systems and are characterized by multiple indoor units connected to a single, largecapacity outdoor unit with multiple refrigerant piping runs. Similar to mini-splits and made by the same mini-split manufacturers, VRF systems (sometimes referred to as VRV) can also vary their capacity. Heat recovery VRF systems can heat one space while cooling another. Like mini-splits, VRF systems will need separate dehumidifiers for most cultivation facility applications. They are another example of existing commercial cooling equipment being applied to the cannabis industry and needing help with dehumidification. With higher efficiencies, VRF can be another cost effective way to control the climate within your grow rooms.

VRF (Variable Refrigerant Flow) Systems are DX split systems and are characterized by multiple indoor units connected to a single, largecapacity outdoor unit with multiple refrigerant piping runs. Similar to mini-splits and made by the same mini-split manufacturers, VRF systems (sometimes referred to as VRV) can also vary their capacity. Heat recovery VRF systems can heat one space while cooling another. Like mini-splits, VRF systems will need separate dehumidifiers for most cultivation facility applications. They are another example of existing commercial cooling equipment being applied to the cannabis industry and needing help with dehumidification. With higher efficiencies, VRF can be another cost effective way to control the climate within your grow rooms.

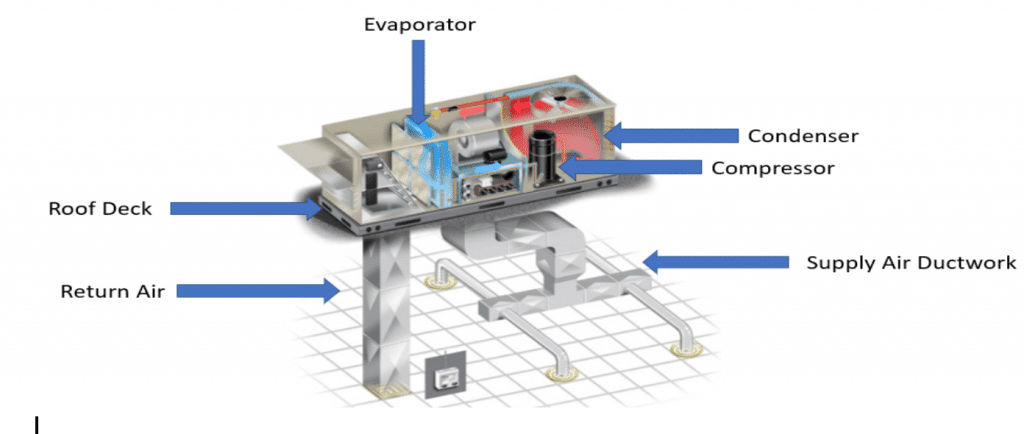

- Packaged DX Systems

Packaged systems have all of the above mentioned components (evaporator, compressor and condenser) in one unit. These must be placed outside and the cool/dehumidified air is ducted into the building. Typically placed on the roof, packaged systems can also be placed on the ground as long as the ductwork can penetrate the walls. The advantages of packaged systems are that they are easy to install and maintain (one unit to install and less overall separate components); no long refrigerant line runs; and they can be made for the purpose of cooling and dehumidifying cultivation rooms with no need for separate/additional dehumidification equipment. Packaged systems built specifically for cannabis cultivators can be more expensive, but with less overall long-term issues and better humidity control.

Packaged systems have all of the above mentioned components (evaporator, compressor and condenser) in one unit. These must be placed outside and the cool/dehumidified air is ducted into the building. Typically placed on the roof, packaged systems can also be placed on the ground as long as the ductwork can penetrate the walls. The advantages of packaged systems are that they are easy to install and maintain (one unit to install and less overall separate components); no long refrigerant line runs; and they can be made for the purpose of cooling and dehumidifying cultivation rooms with no need for separate/additional dehumidification equipment. Packaged systems built specifically for cannabis cultivators can be more expensive, but with less overall long-term issues and better humidity control.

- Chilled Water Systems

Chiller systems involve a large outdoor unit that chills water (air-cooled chiller) which is then piped to multiple indoor units for cooling and dehumidification. Rather than running refrigerant piping, water piping is used instead and chilled water can be piped much further than refrigerant. Chiller systems can be a cost effective option for larger indoor cultivation facilities with larger cooling and dehumidification loads. The chiller itself will have to be paired with appropriate indoor units made for cannabis growers and sometimes the indoor units and chillers are made by different manufacturers.

Chiller systems involve a large outdoor unit that chills water (air-cooled chiller) which is then piped to multiple indoor units for cooling and dehumidification. Rather than running refrigerant piping, water piping is used instead and chilled water can be piped much further than refrigerant. Chiller systems can be a cost effective option for larger indoor cultivation facilities with larger cooling and dehumidification loads. The chiller itself will have to be paired with appropriate indoor units made for cannabis growers and sometimes the indoor units and chillers are made by different manufacturers.

- Purpose-Built Split Systems:

Many HVACD equipment manufacturers now make indoor units specifically built for cannabis cultivation. These air handlers can be DX or chilled water and are built with large dehumidification coils and reheat coils. They will be connected to outside heat rejection units, either air-cooled condensers (DX) or chillers. Highly specialized with control sequences made for cannabis cultivation, these systems can be expensive, and yet be efficient, long-term solutions for your grow room climate control.

Many HVACD equipment manufacturers now make indoor units specifically built for cannabis cultivation. These air handlers can be DX or chilled water and are built with large dehumidification coils and reheat coils. They will be connected to outside heat rejection units, either air-cooled condensers (DX) or chillers. Highly specialized with control sequences made for cannabis cultivation, these systems can be expensive, and yet be efficient, long-term solutions for your grow room climate control.

While the above list represents the basic equipment offerings available to cannabis cultivators, there are many variations and configurations of these systems which we can help you decipher. There are different types of packaged units and different types of split systems all with some special features that their makers will promote as best for your application. There are also different types of chillers and dry coolers, different dehumidification strategies and vastly different types of controls.

Cultivation Sector Consulting is not affiliated with any equipment manufacturer and we do not take any payment or accept any perks from any of them! We work for you and we are here to help you choose the system that is right for your unique facility.

Contact Us Today for Help Choosing Your Cannabis Climate Control System